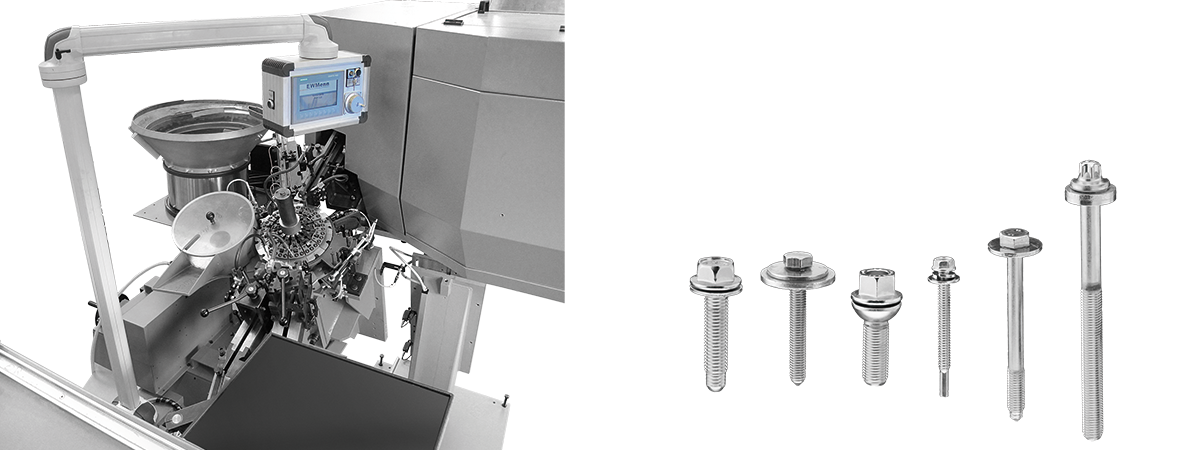

Test Center

The test center at EWMenn is equipped with up to date technology including an AF 141 Flat Die Thread Rolling Machine. The machine is equipped with modern features including hydraulic die carrier clamping, push button die match and electric height adjustment. This way, safe and easily repeatable adjustments are guaranteed. This is critical when testing. Maximum die length that can be used in the AF 141 is 230/225mm or Waterbury #40. Shorter dies can, of course, be used as well. The machine is also equipped with the newest Brankamp Model X-5 Process Control System with actual forming tonnage calibrated sensors in all four pressure channels. Integration of the X-5 into our Adaptive Die Match (ADM®) System enables complete process control and documentation as well as continuous real-time monitoring and optimization of die match for each part passing through the dies. This provides the best possible circumstance for testing and development projects.

Currently the machine is also equipped with a warm rolling system that allows heating of the blanks before rolling in order to - for example - roll special materials like titanium or to facilitate higher degrees of deformation.