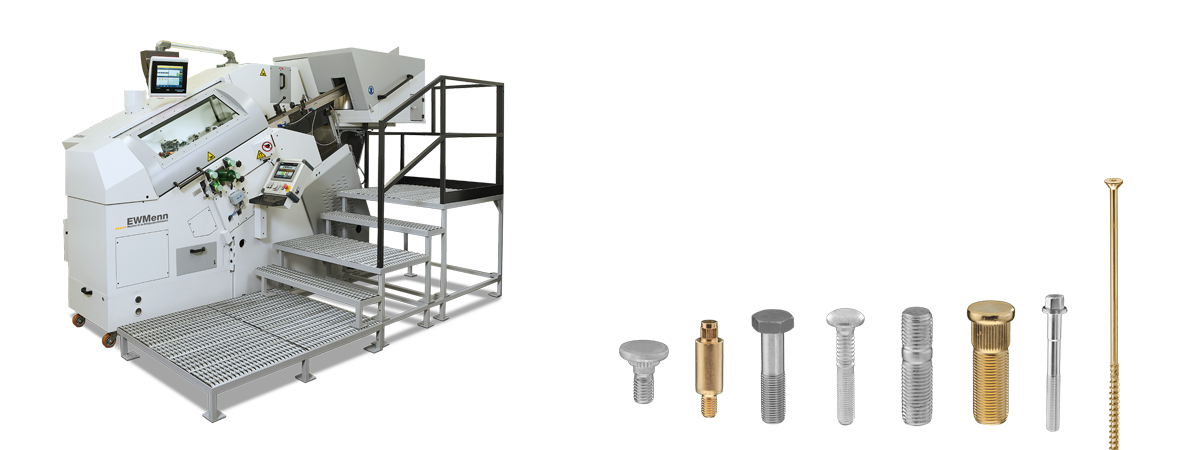

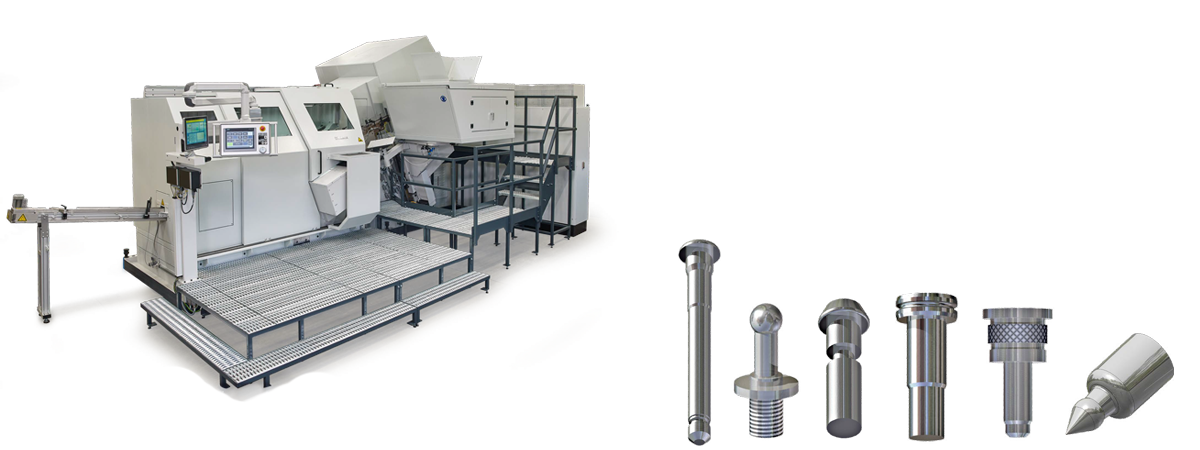

New Model AF 141 Flat Die Thread Rolling Machine: Premiere at Wire 2018

20 years after the introduction of the inclined Flat Die Thread Rolling machines AF 12 and AF 14 these large AF models have been extensively re-engineered. This newest generation has already been thoroughly tested and delivered to several of our customers. At Wire 2018 the AF 141 was shown to the public for the first time.

Like their predecessors, the AF 121 and AF 141 have identical roots. The main difference between the two models is the ram stroke, permitting a maximum die size of:

- AF 141: 230/255mm / WB#40 / TR6

- AF 121: 190/210mm / WB#30 / TR5

The new AF 121 / AF 141 generation features a number of innovations, including:

- The ramslide has been changed to a T-shape, offering even higher precision and longer service life, along with increased rigidity.

- Better accessibility and easier adjustment of the rail system and railcovers.

- The machine cover has been redesigned to allow better access for the operator while eliminating coolant dripping down from opened doors.

- As on all EWMenn models the covers are designed to offer maximum accessibility during operation while conforming to strict up to date CE safety standards.

Of course, state of the art process control technology including the Adaptive Die Match system ADM®, developed in cooperation with Marposs/Brankamp, was on board as well as a connection to the Wafios 4.0 data system.

Other options shown included Hydraulic Die Carrier Clamping, Servo Drive with Electronic Handwheel, Push Button Adjustments for Die Match, Rail and Feeder Height, Sorting Flap for non-conform parts and more.

Today one AF 141 is in EWMenn´s own Testcenter where it is equipped with an induction heating system available to customers for testing of dies, parts and rolling processes. Since its introduction the Testcenter has regularly been booked by customers.

EWMenn – INNOVATION IS WHAT WE LIVE.